The Basic Principles Of Plastic Pallet

Wiki Article

4 Simple Techniques For Plastic Pallet

Table of ContentsThe Ultimate Guide To Plastic Pallet8 Simple Techniques For Plastic PalletPlastic Pallet Can Be Fun For AnyoneIndicators on Plastic Pallet You Need To KnowThe 20-Second Trick For Plastic PalletThe Only Guide to Plastic PalletNot known Details About Plastic Pallet The Definitive Guide for Plastic Pallet

This is different from the open and closed-deck pallets, which have an open bottom. The load carried by the pallet is also distributed to the bottom deck; this makes the pallet durable. A double-face pallet may be a reversible or non-reversible pallet: Reversible Pallets Have identical designs on their top and bottom decks.Non-Reversible Pallets Have different top and bottom decks and weigh less than reversible pallets. The top deck has more plastic material to support the product when it is mounted on the pallet. Double-Wing Plastic Pallets Double-wing plastic pallets have top and/or bottom deck that extend beyond the surface of the stringers or blocks, creating more space for the products.

Fascination About Plastic Pallet

These special types of pallets are: Drum Pallets Drum pallets are used to hold drums and containers filled with oil, chemicals, and other liquid substances during transportation and storage. The drum fits in a customized recessed ring in the top deck built to hold it in place; other drum pallets may not have these recessed rings.

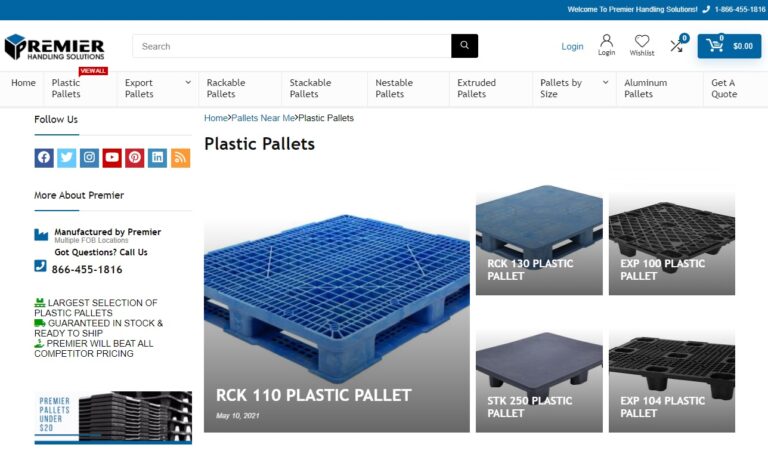

Stackable Pallets Stackable pallets have solid bottom support that gives stability to the products loaded on top of them when they are placed on top of another loaded pallet. They are commonly used in warehouses to stack goods efficiently and to save floor space. Nestable Pallets Nestable pallets have hollow legs on their corners to enable stacking of empty pallets when they are not loaded.

Plastic Pallet Fundamentals Explained

In addition to geographical compliance, it is important to consider the application of the plastic pallet before selecting a size. Conclusion Plastic pallets are rigid structures that provide stability to goods during transportation or storage. They are one of the important tools in the supply chain and logistics industry. Plastic pallets offer many advantages over pallets constructed from other materials.

Unknown Facts About Plastic Pallet

All plastic pallets are manufactured by a molding process. There are several molding techniques to choose from depending on the application and desired characteristics of the pallet. All pallets, including plastic pallets, come in standardized sizes as sanctioned by different governing bodies in a particular region. This is to eliminate the difficulties that may arise during handling and transportation.

The Definitive Guide to Plastic Pallet

2. Chemical Manufacturing and Shipping Chemical manufacturers and shippers can have very different needs depending on the products they are using pallets for, and the moldability of plastic is useful in this situation. If drums of chemicals are being transported, pallets can be formed with a recessed ring on the deck for drums to fit in.This makes cleaning spills much easier and may also prevent spilled chemicals from leaking to surfaces other than the pallet. In addition, the pallet can be made from slip or corrosion resistant material, making it more durable for that environment. 3. Food Processing and Production Plastic pallets are easy to clean and are sanitary for situations involving food.

The Best Guide To Plastic Pallet

This is especially important for facilities that are involved in food production or processing, since all surfaces why not check here that could come into contact with food must meet certain hygienic standards. These operations almost exclusively use plastic pallets since it can be difficult keeping wood to those standards. A simple you could look here wash with water or cleaning solution will sanitize a plastic pallet.In-Store Displays There are wooden pallets that are produced in a way to best fit being displayed inside a store, but some may prefer a plastic pallet for this job. While wooden pallets can look very clean and compliment products well, they will eventually wear over time and there is a risk of broken deck boards or exposed nails after repeated moving.

5 Simple Techniques For Plastic Pallet

5. Airline Shipping Certain plastic pallets are designed to be lightweight and are ideal for transporting goods on aircraft. This is significant when all ounces and pounds are counted and analyzed. These pallets are also designed to be stackable as well as lightweight, so they take up less space when not being used on a return trip.If pallets are going from a distribution center to a grocery store, for example, those same pallets would be delivered back to the original distribution center. Then the cycle repeats. Most plastic pallets are used in this type of shipping system, due to their higher upfront cost but also because of their enhanced durability.

Plastic Pallet Can Be Fun For Anyone

Additional Considerations While plastic pallets are useful in the situations mentioned above, wooden pallets will likely remain the workhorse of the industry. Wood is more cost effective and can easily be repaired. Plastic pallet. Plastic pallets have more upfront cost and are usually kept in closed loop systems, but are much more durable.Pallets are essential for any business that ships products. They ensure your products see this reach their destination safely, make shipping easier and reduce the need for other packaging materials. It is important to that you start by choosing the right pallet. In the past, wood pallets were the default choice for most businesses.

Report this wiki page